Our Products

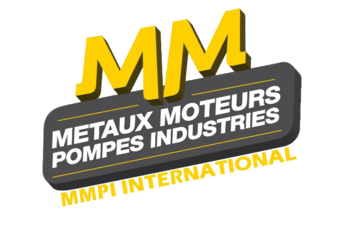

WILO – Centrifugal Pump – HELIX Series

Centrifugal Pump

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

The pumps can be adapted to certain specific data (e.g. motor protection, motor efficiency class IE4, Wilo-Helix pumps with VdS, ATEX approval, extended ambient temperature range). These pumps are available with an integrated vertical frequency converter with inline connections.

APPLICATIONS

- Water distribution and collective overpressure

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire protection installations

- Washing stations

- Irrigation

EQUIPMENT / FUNCTION

- Corrosion resistant impellers, diffusers and stepped bodies

Spécifications / Specifications

Technical data

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix V 2, 4, 6, 10, 16:

- Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- For aggressive media

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Helix V 22, 36, 52:

- Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- For aggressive media

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Type key

| Example: | Helix V(F) 2202/2-1/16/E/X/KS/../1-400-50/-38FF265 |

| Helix V(F) | Vertical high-pressure multistage centrifugal pump in in-line design(F) = VdS certified pump version |

| 22 | Flow rate in m3/h |

| 02 | Number of impellers |

| 2 | Number of trimmed impellers (optionally) |

| 1 | Pump material |

| 1 = Pump housing 1.4301 (AISI 304) Hydraulics 1.4307 (AISI 304L) | |

| 2 = Pump housing 1.4409 (AISI 316L) Hydraulics 1.4404 (AISI 316L) | |

| 3 = Pump housing EN-GJL-250 (cataphoretic-coated) Hydraulics 1.4307 (AISI 304L) | |

| 4 = Monobloc pump housing EN-GJL-250 (cataphoretic-coated) Hydraulics 1.4307 (AISI 304L) [Only Helix VE 22.. and larger] | |

| 16 | Maximum operating pressure in bar |

| 16 = 16 bar (PN 16 flange) | |

| 25 = 25 bar (PN 25 flange) | |

| 30 = 30 bar (PN 40 flange) | |

| E | Gasket type E = EPDM V = FKM |

| X | “X-Care” special version |

| K | Cartridge type mechanical seal |

| S | The coupling guard is on a line with suction and discharge ports of the pump |

| 1 | 1 = 1~ (alternating current)None = 3~ (three-phase current) |

| 400 | Connection voltage in V |

| 50 | Frequency in Hz |

| -38FF265 | Diameter motor shaft – lantern size (pump version without motor) |

| .. | Optional |

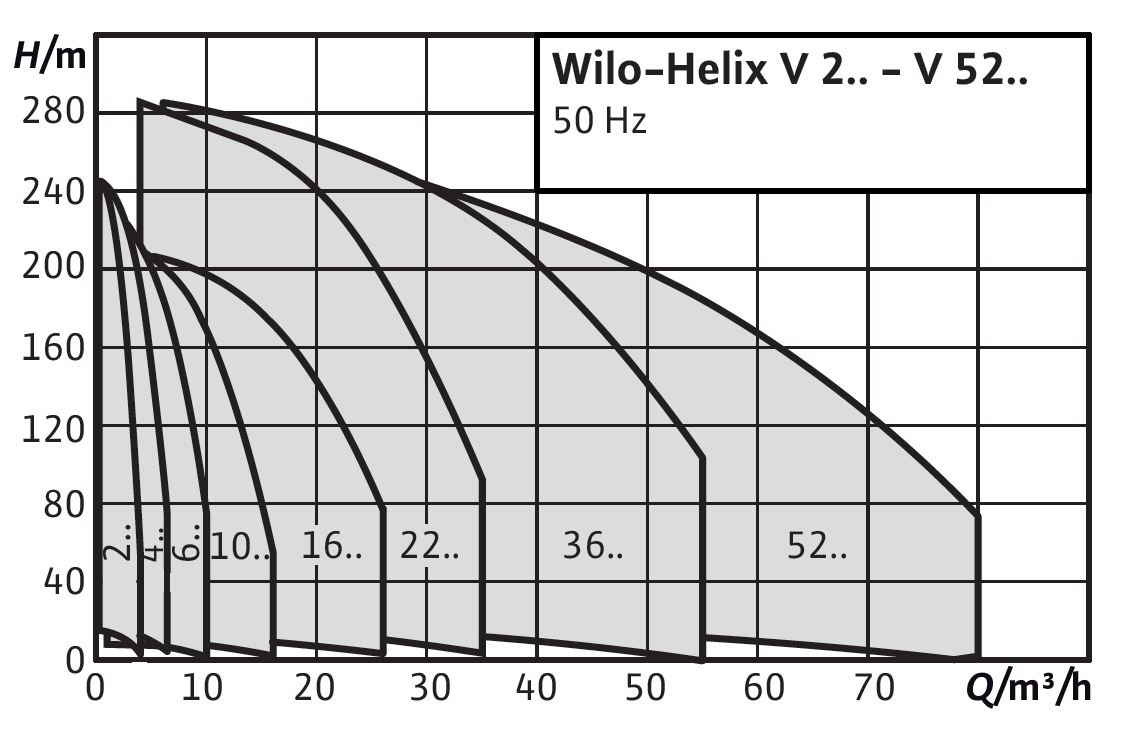

Courbes / Performance Curve